Thermoplastic elastomers (TPEs) are a unique class of materials that exhibit both the elastic properties of rubber and the processing advantages of plastics. This duality often leads to the question: Is TPE a rubber or a plastic? To answer this, it’s essential to delve into the characteristics, classifications, and applications of TPEs.

Understanding Thermoplastic Elastomers (TPEs)

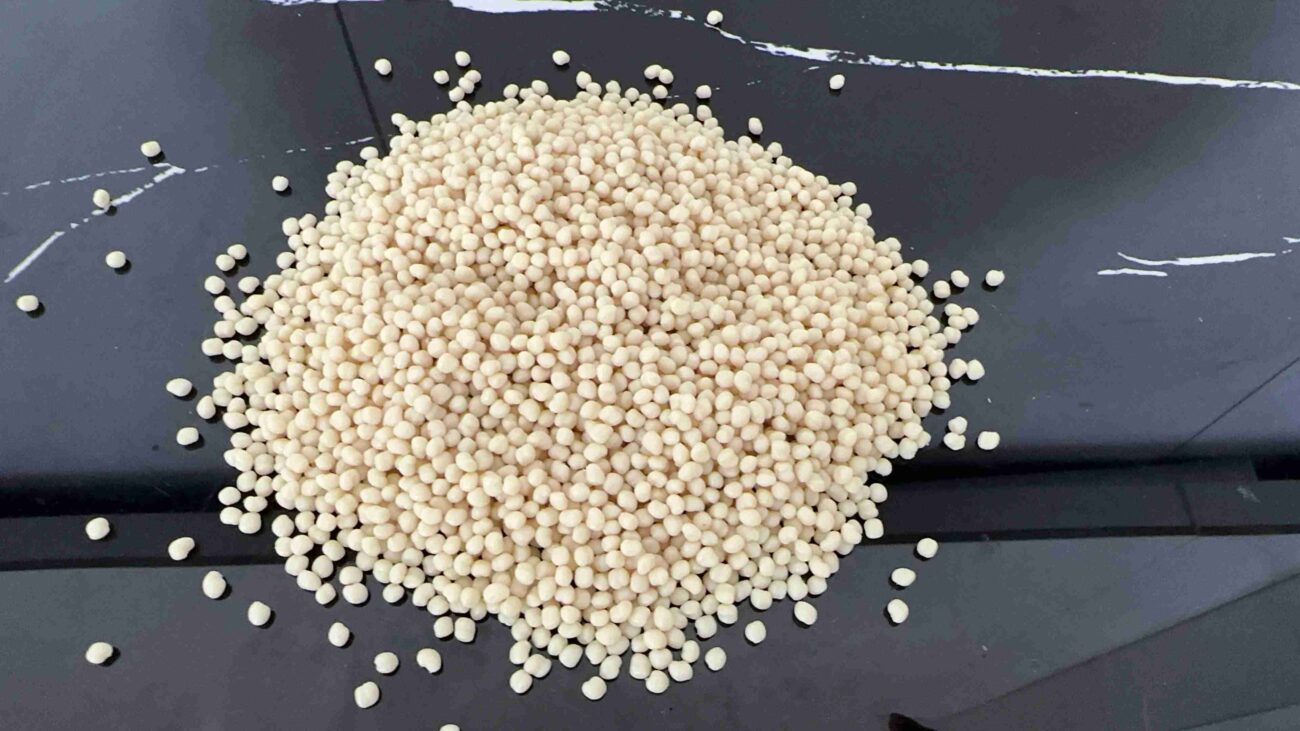

TPEs are polymers that combine the elasticity of rubber with the moldability of plastics. Unlike traditional thermoset rubbers, which require curing and cannot be remelted, TPEs can be repeatedly melted and reshaped. This recyclability and ease of processing make them highly versatile in various industries.

Key Characteristics of TPEs:

- Elasticity: TPEs can stretch and return to their original shape, similar to rubber.

- Processability: They can be processed using standard plastic fabrication methods like injection molding and extrusion.

- Recyclability: TPEs can be remelted and reused, reducing waste.

- Versatility: They can be formulated to achieve a wide range of hardness levels and properties.

Classifications of TPEs

TPEs encompass various types, each with distinct properties and applications:

- Styrenic Block Copolymers (SBCs): Includes TPE-S, TPR, and TPS. These are often used in applications requiring flexibility and a soft touch, such as grips and seals.

- Thermoplastic Polyolefins (TPOs): Composed of a blend of polypropylene (PP) and elastomers like ethylene-propylene rubber (EPR). TPOs are commonly used in automotive parts due to their durability and impact resistance.

- Thermoplastic Vulcanizates (TPVs): A subset of TPOs, TPVs are dynamically vulcanized blends of PP and EPDM rubber. They offer enhanced elasticity and heat resistance, making them suitable for automotive seals and hoses.

- Thermoplastic Polyurethanes (TPUs): Known for their excellent abrasion resistance and flexibility, TPUs are used in applications like footwear, cables, and medical devices.

- Thermoplastic Copolyester Elastomers (TPEEs): These materials provide high mechanical strength and chemical resistance, ideal for applications such as automotive components and industrial hoses.

TPE vs. TPR: Clarifying the Terms

The terms TPE and TPR are often used interchangeably, but they have specific distinctions:

- TPE (Thermoplastic Elastomer): A broad category encompassing all thermoplastic elastomers.

- TPR (Thermoplastic Rubber): Typically refers to styrenic-based TPEs, especially those derived from SBS (styrene-butadiene-styrene) or SEBS (styrene-ethylene-butylene-styrene) block copolymers. In some regions, TPR is used as a general term for all TPEs, leading to potential confusion.

Applications of TPEs

The versatility of TPEs allows them to be used across various industries:

- Automotive: Components like seals, gaskets, and interior trim benefit from TPEs’ flexibility and durability.

- Consumer Goods: Products such as toothbrush grips, remote control buttons, and soft-touch handles utilize TPEs for comfort and grip.

- Medical Devices: TPEs are used in tubing, seals, and flexible connectors due to their biocompatibility and sterilization capabilities.

- Footwear: Soles and inserts made from TPEs provide cushioning and flexibility.

Market Availability and Pricing

TPEs are widely available in the market, with prices varying based on type, grade, and application requirements. For instance, TPVs, known for their enhanced properties, may be priced higher than standard TPEs. Manufacturers and suppliers offer a range of TPE materials tailored to specific applications, ensuring that designers and engineers can select the most appropriate material for their needs.

Conclusion: Rubber or Plastic?

Thermoplastic elastomers embody the best of both worlds: the elasticity of rubber and the processability of plastic. This unique combination allows them to be molded and remolded like plastics while providing the flexibility and resilience of rubber. Therefore, TPEs are neither strictly rubber nor plastic but a hybrid material that bridges the gap between the two, offering unparalleled versatility in modern manufacturing.

For those interested in exploring TPE materials for their projects, numerous suppliers offer a variety of options to suit different applications and performance requirements.

Ready to elevate your products with premium thermoplastic elastomer solutions? At Sutper, we specialize in delivering customized TPE materials tailored to your unique industry needs. Whether you’re seeking superior durability, flexibility, or innovative performance features, our expert team is here to support your vision.

Contact us today to discuss your requirements or request a free sample. Let’s work together to create exceptional products that exceed your expectations. Discover the Sutper advantage—your trusted partner in TPE innovation.